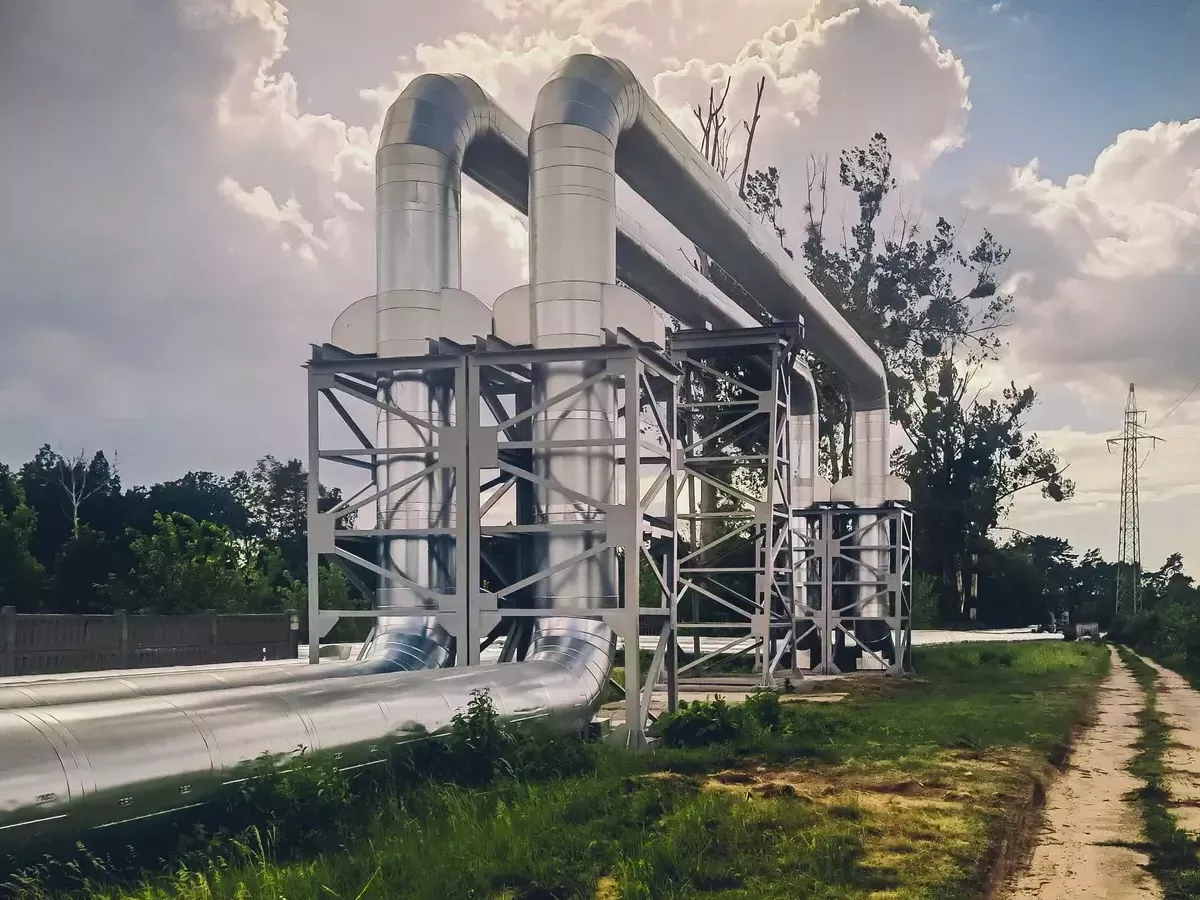

Izolacje termiczne rurociągów

Firma ELEKTROTERMEX jest producentem otuliny termoizolacyjnej ETX-PUR w łubkach ze sztywnej pianki poliuretanowej z blachą ocynkowaną, aluminiową i w płaszczu z folii „Izofrex” do stosowania na napowietrznych rurociągach sieci cieplnych o średnicy od 15 do 1600 mm. Spółka oferuje w tym zakresie nie tylko gotowy produkt, ale przede wszystkim kompleksowe usługi modernizacji istniejących rurociągów sieci cieplnych.

Dzięki spełnieniu tak wielu rygorystycznych warunków procesu spieniania mamy pewność iż dostarczone do naszych Klientów izolacje są wysokiej jakości i spełniają wszelkie normy dopuszczające je do obrotu na rynku polskim. Wszystkie materiały jak również i same otuliny posiadają stosowne Aprobaty techniczne, Atesty higieniczne oraz mają Atest na samogaśnięcie wydany przez Zakład Badań Ogniowych warszawskiego ITB.