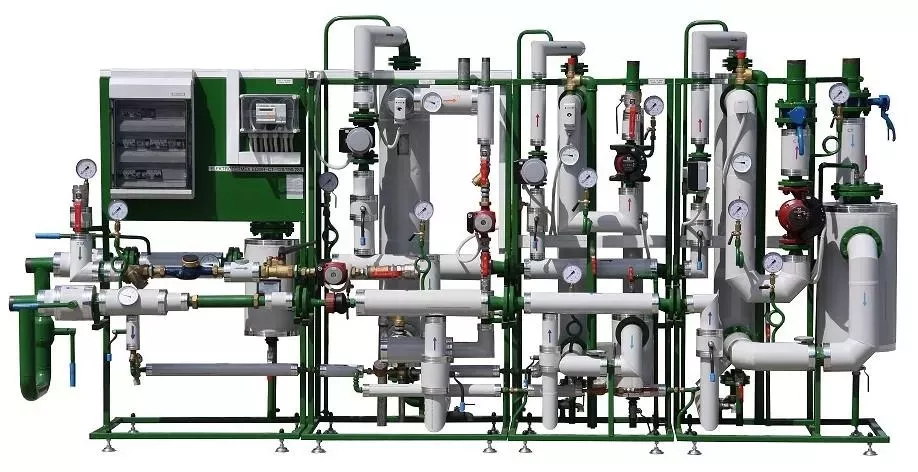

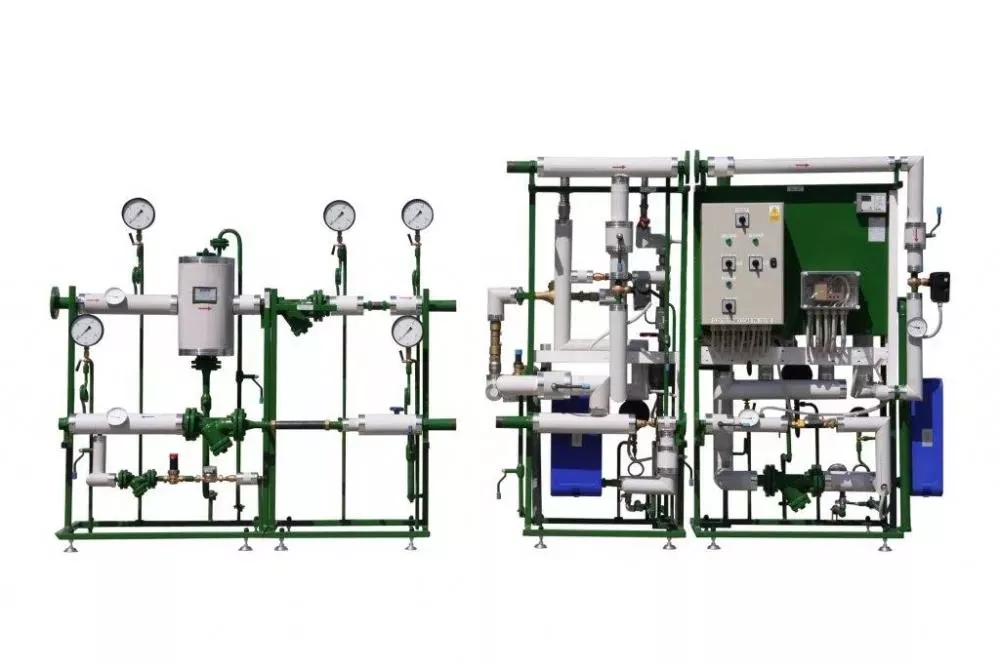

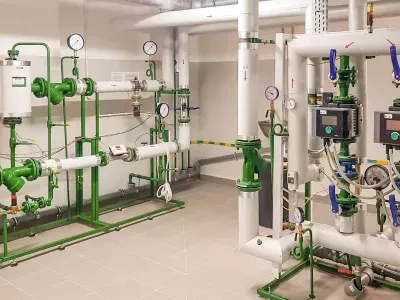

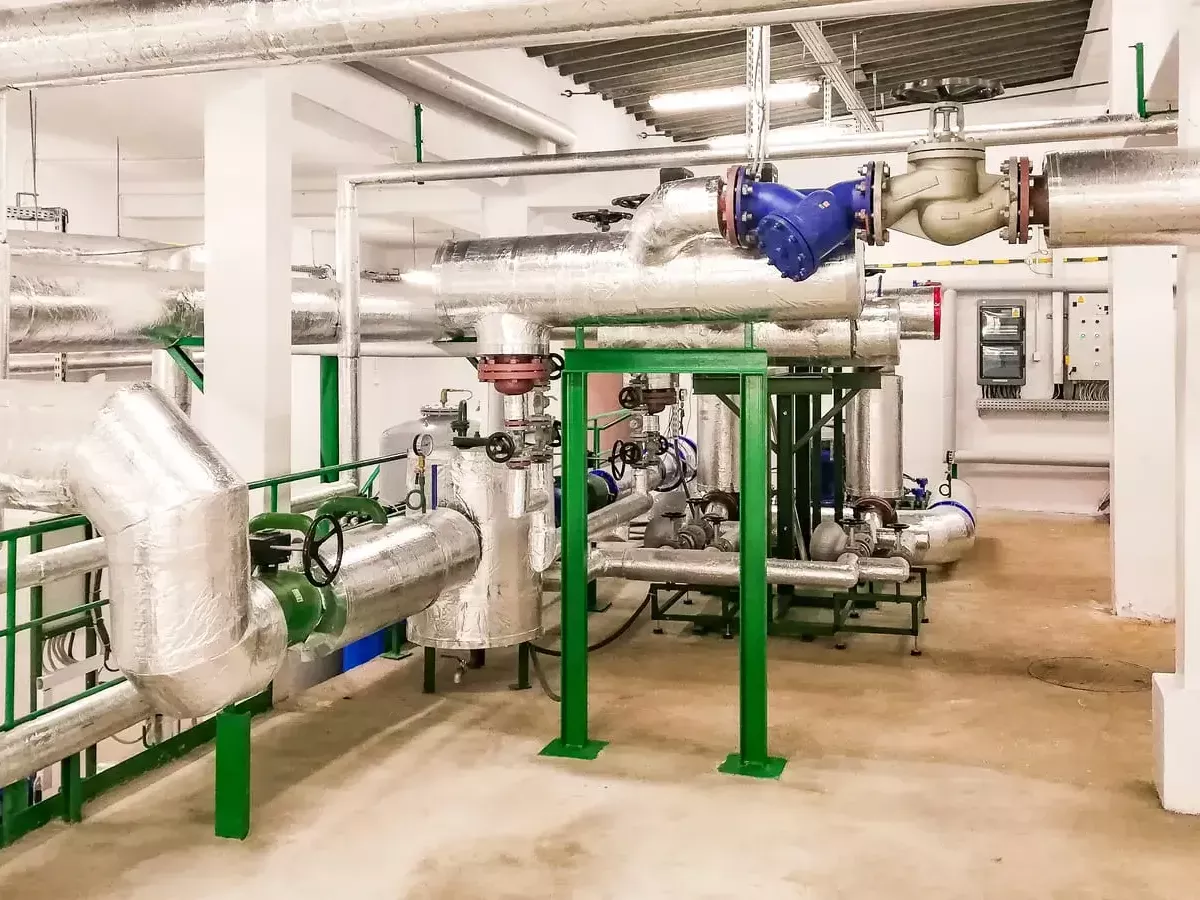

Kompaktowe węzły cieplne

Wykonujemy począwszy od projektu, do wyprodukowania włącznie węzły cieplne zarówno na potrzeby centralnego ogrzewania, ciepła technologicznego, jak i przygotowania ciepłej wody użytkowej. Produkujemy węzły jedno-, dwu- i wielofunkcyjne o mocy cieplnej od kilku kW do stacji cieplnych o mocy kilkunastu MW. Stosujemy materiały i urządzenia renomowanych, sprawdzonych producentów posiadające wymagane atesty i certyfikaty.

Co nas wyróżnia?

Indywidualne wykonanie: Każdy węzeł cieplny powstaje na podstawie indywidualnego projektu; wykonanie "na miarę".

System jakości: System zapewnienia jakości ISO 9001:2000, obejmujący projektowanie, produkcję i serwis potwierdza dotrzymywanie wysokich standardów wykonania węzłów cieplnych w naszej firmie.

Oznakowanie CE: Zgodnie z dyrektywami UE, a od 1 maja 2004 roku również przepisami krajowymi, kompaktowy węzeł cieplny musi posiadać oznakowanie CE. Nasza firma jest certyfikowana przez BV i wszystkie nasze węzły mają znak CE jako potwierdzenie spełnienia wszystkich dyrektyw nowego podejścia.